The "Horizontal Circulating Fluidized Bed Combustion Technology" is a world-leading efficient and clean biomass combustion technology jointly developed by Nowva Energy and Tsinghua University.

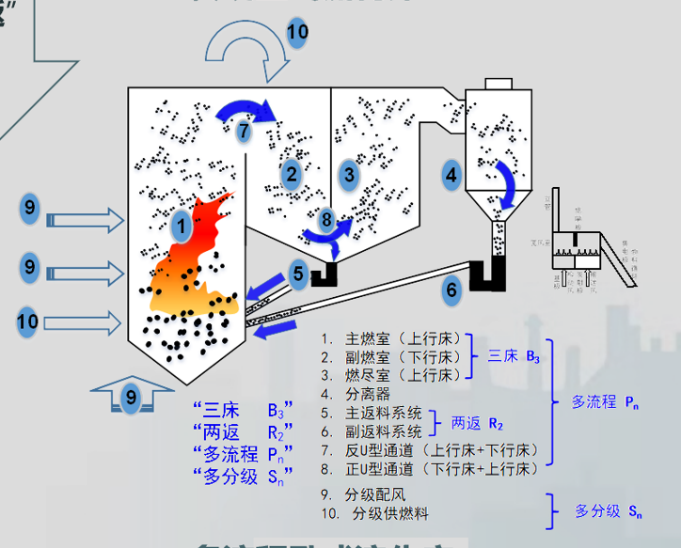

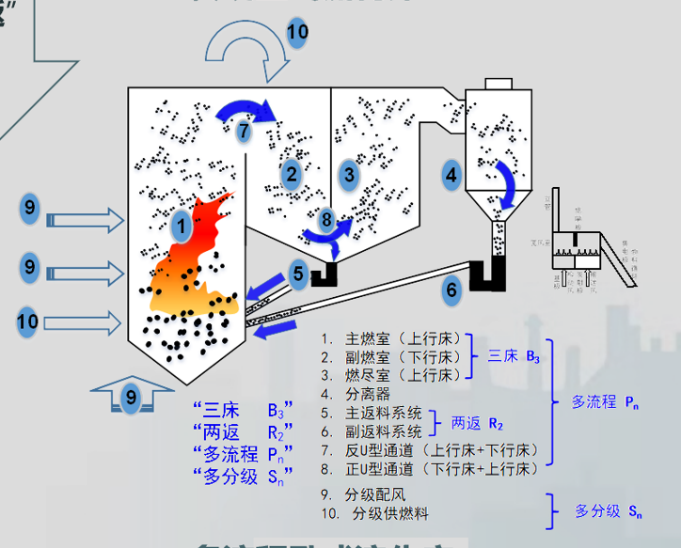

This technology innovatively puts forward the concept of "three-bed, two-return and multi-pass" horizontal circulating fluidized bed, which effectively solves the problems of low thermal efficiency, high initial NOX emission and poor variable load operation capacity of small and medium-sized biomass fired boilers. It fills the technical gap of small and medium-sized fluidized bed boilers worldwide.

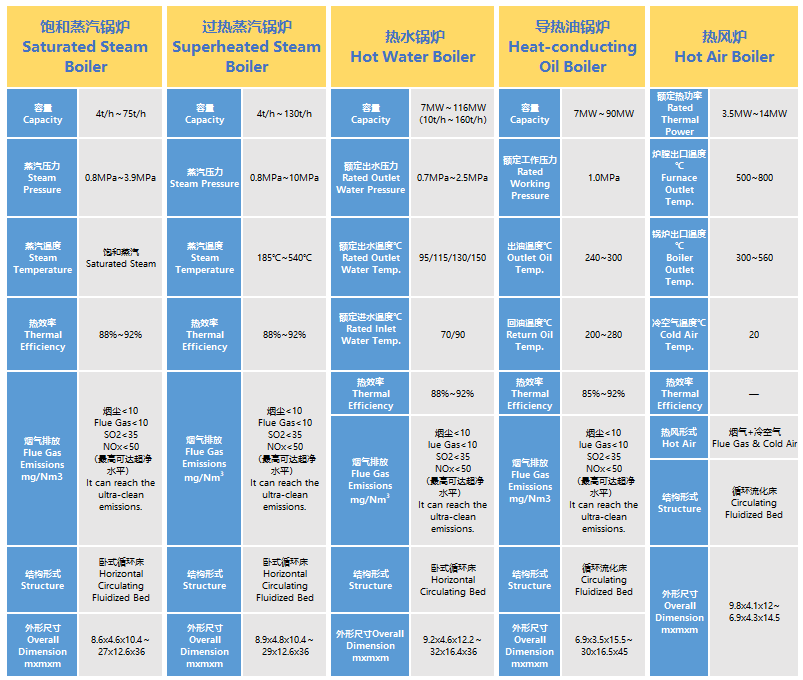

Boiler Series

Heat recovery method: various parameters steam, hot water, hot air, power generation

Steam output: ≤130t/h; Steam pressure: ≤ 9.8 MPa, Steam Temp: ≤540℃

Product Advantage

Four ultra characteristics: Ultra-wide fuel adaptability, ultra-high actual operation thermal efficiency, ultra-long operation period and less maintenance, ultra-low environmental protection operation cost.

Ultra-wide Fuel Adaptability

Ultra-wide Fuel Adaptability

Solid fuels with a low heating value of 6.3-25.0MJ/kg are suitable for the boiler . It can meet the pure burning or blending burning of agricultural and forestry wastes and biomass industrial wastes. The operation is steadily, which can realize the clean and efficient operation under the load between 30%-110%.

Ultra-high Thermal Efficiency.

Ultra-high Thermal Efficiency.

The actual operation thermal efficiency is 80%-92%, up 20 percentage point comparing with the conventional small and medium sized industrial boiler, a remarkable energy conservation effect.

Ultra-long Equipment Operation Period and Less Maintenance.

Ultra-long Equipment Operation Period and Less Maintenance.

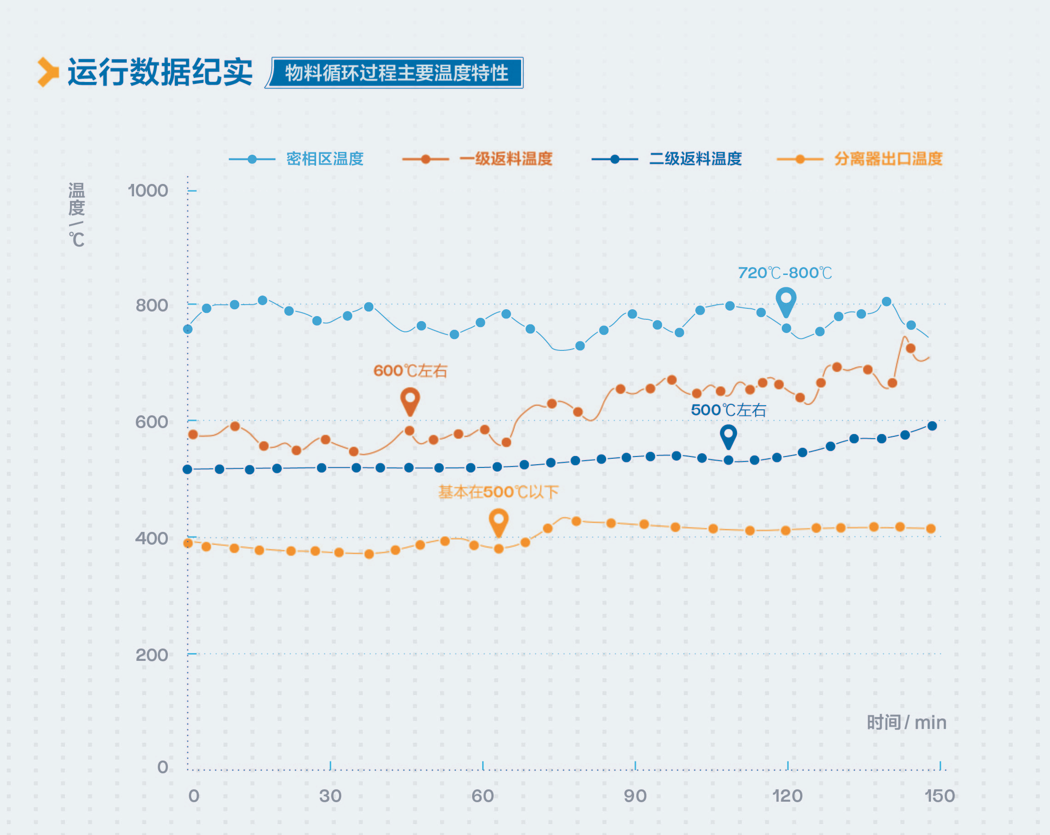

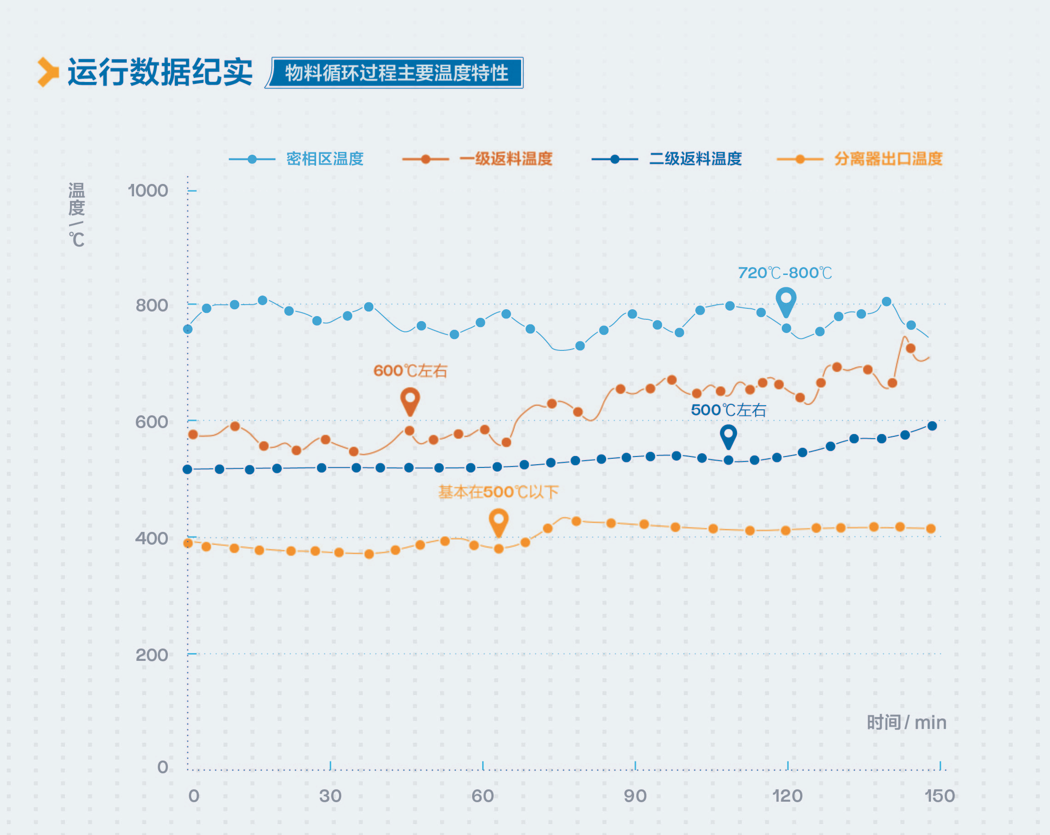

The annual operation time is over 8000 hours which has realized 225 days' continuous operation. The two-stage separation of materials at high temperature and medium temperature has strong resistance to ash accumulation and slagging, making it more suitable for biomass fuels with low ash melting points. The maintenance cycle is extended and the maintenance cost is low.

Ultra-low Environmental Protection Operation Cost.

Ultra-low Environmental Protection Operation Cost.

Low temperature combustion and staged air distribution reduce the NOX initial emission concentration to lower than 100mg/m3 from 500 mg/m3. With the assistance of SNCR method, an ultra-low emission standard of 50 mg/m3 can be met.

Industry Comparison

The patented "three beds, two returns" horizontal circulating fluidized bed technology of Nowva Energy innovatively solves the global problem in miniaturizing fluidized bed boilers. This technology fills the gap of 35t/h and below fluidized bed boilers worldwide. The technology is significantly superior to similar products in terms of various technical performace when applied to small and medium-sized boilers below 75t/h.

| Project | Horizontal CFB boiler | Conventional CFB boier(vertical) |

|---|---|---|

| Specification | ≤110t/h | ≥75t/h |

| Thermal efficiency | ≥88% | / |

| Separation temp | ≈500℃ | ≈850℃ |

| NOX initial emission≤100 mg/m³ | ≤100 mg/m³ | ≈500 mg/m³ |

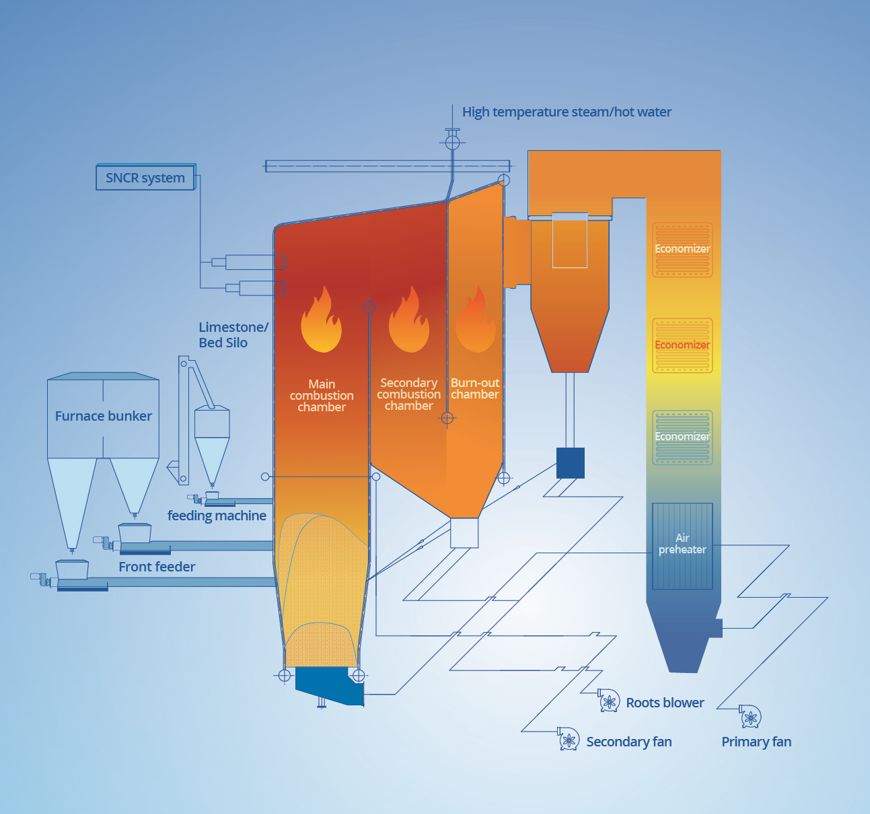

Principle of Combustion Technology for New Type of Horizontal Circulating Fluidized Bed Boiler

Three-stage Furnace and Two-stage Material

circulating increases the effective combustion period and improve combustion efficiency

Medium Temperature Separation, Temperature 500℃

two-stage separation to prevent post-combustion and separator coking.

Low Temperature Combustion and Stage Air Distribution

The initial emission of NOX is lower than 100mg/m3.

Process Flow

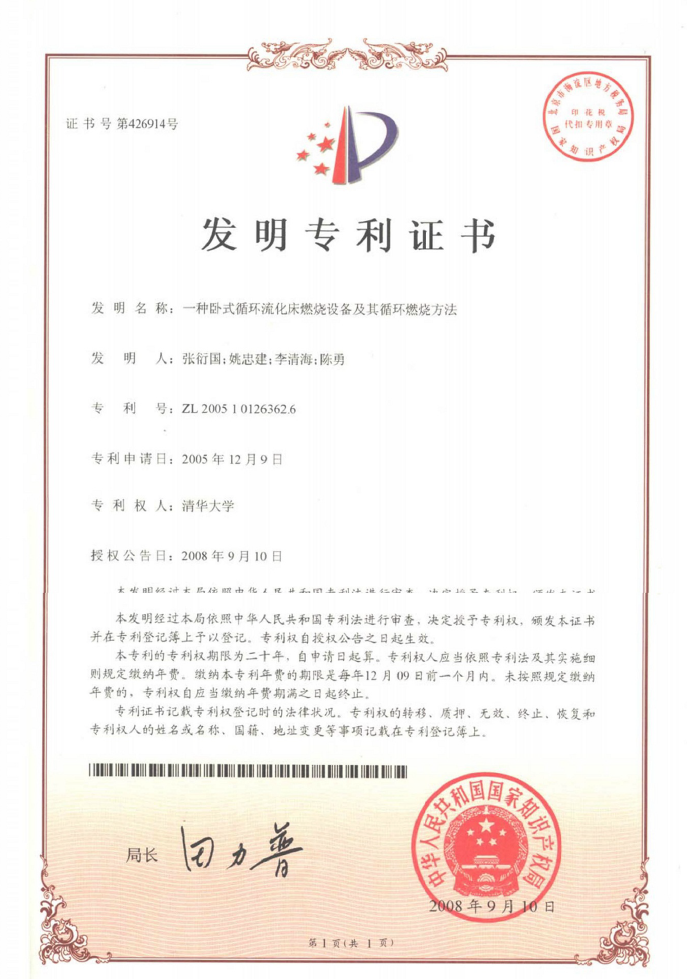

Intellectual Property

37

Invention Patents

2

International PCT Patents

45

Patents for Utility Models

Invention Patents

Invention Patent Certificate

2023

Preponderant Unit of Beijing Intellectual Property

2023

Gold Award at the Geneva International Invention Exhibition

2022

China Patent Excellence Award

2021

Intellectual Property Management System Certification

2018

First Prize of Energy Conservation and Environmental Protection Patent

Please contact us if needed.

Contact Us

Contact Us

联系热华能源

如果您对我们的技术感兴趣,又或者是技术相关的问题,我们很乐意为您提供帮助。

Three-stage Furnace and Two-stage Material

Three-stage Furnace and Two-stage Material

circulating increases the effective combustion period and improve combustion efficiency

Medium Temperature Separation, Temperature 500℃

Medium Temperature Separation, Temperature 500℃

two-stage separation to prevent post-combustion and separator coking.

Low Temperature Combustion and Stage Air Distribution

Low Temperature Combustion and Stage Air Distribution

The initial emission of NOX is lower than 100mg/m3.

400 000 5570